Quality Assurance

Stringent Quality Control System

At YoLong Electronics, we prioritize providing top-quality electronic components to our clients. We have established two advanced Quality Control Centres in Hong Kong and Shenzhen, spanning 500 square meters, and equipped with over 30 sets of inspection equipment and over 20 professional engineers. Our QCS management system covers all inspection processes, from warehousing to electrical testing, ensuring compliance with international standards. Our mission is to ensure that our customers only receive genuine and functional electronic components, all products will be undergone strict multi-step inspection as below.

Testing equipment

Inspection

Ensure That All Packaging, Labels And Components Conform With The Original Manufacturer Specifications.

X-ray Testing

Ensure That All Components Are Original And Consistent With The Original Manufacturer Specifications.

Acetone Verification

Ensure That All Component Markings Are Consistent With The Original Manufacturer Specifications.

ESD Compliant Environment

ESD-Compliant Warehouse Following The DIN Norm EN-61340-5-1 Standard & ISO9001.

Component Baking

Ensures That All Shipped Products Comply With The Manufacturers Required MSL Standard.

Tape & Reeling

As An Added Service, If Required, We Can Tape And Reel Components In Order To Save Our Clients Valuable Time And Money.

Decapsulation

Offers Effective Decapsulation Of IC Packages, Gaining Access To The Die Inside, Necessary For Electrical Testing, Counterfeit Prevention, And More.

Chip Programmer

Verify Existing Chip Data, Buffer Data To Be Written To The Chip, Check Whether The Chip Is Empty, Or Erase The Chip.

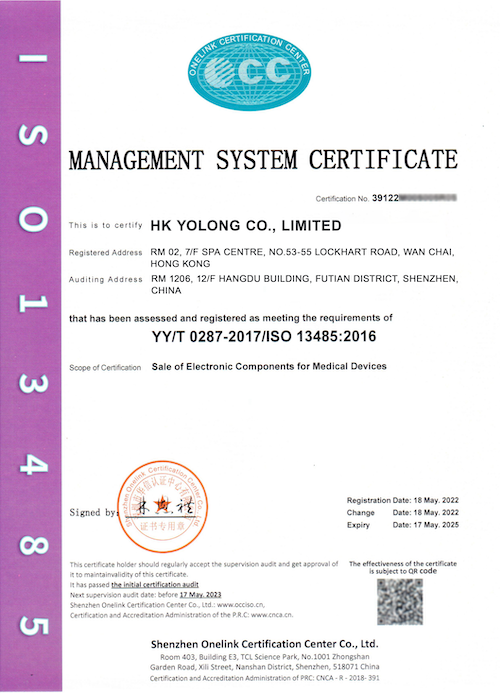

certifications